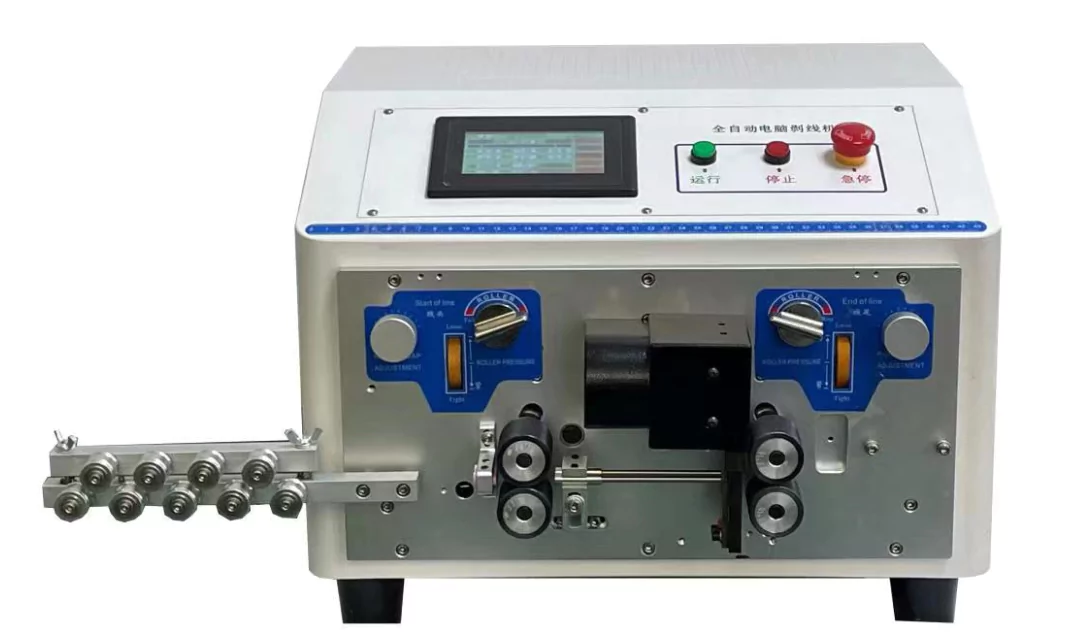

Experiencing issues with your computerized automatic wire cutter and stripper? When your machine struggles to strip wire ends effectively, a few common culprits are usually to blame. Here’s a comprehensive guide to quickly diagnose and resolve these problems.

Diagnosing Unstripped Wire Ends

If your machine isn't consistently stripping wire ends, begin by inspecting the cutting blades. Worn or damaged blades can lead to wires being clamped improperly or even cut, so assess their condition and replace them if necessary.

Next, focus on the machine's pressure settings. The pressure directly impacts stripping quality. Too much pressure can cause wires to be clamped excessively, while too little might result in incomplete stripping. Adjust this carefully to find the optimal setting for your wire type.

Consider the stripping heads themselves. Ensure you're using the correct heads for the wire's diameter and material. Mismatched heads are a common cause of poor stripping performance.

The cutting blade depth also plays a crucial role. If the blade isn't deep enough, it won't penetrate the insulation; if it's too deep, it could sever the wire itself. Fine-tune this depth to ensure precise insulation removal.

Beyond Machine Settings: Wire and Environment

Sometimes, the issue isn't with the machine settings but with the wire quality. Hard-to-strip insulation on poor-quality wire can hinder the process. Opting for higher-quality wire can often resolve this.

Also, confirm the wire is correctly installed in the machine's clamping device. Improper loading can prevent the machine from operating as intended.

Addressing Feed and Mechanical Issues

Pay attention to the cutting head of your automatic wire stripper. Adjust its position based on the wire's diameter to ensure the blade fully strips the insulation. Don't forget to check the blade's sharpness; a dull blade will require replacement.

Inspect the machine's track and conveyor belt for any foreign objects or misalignments that could be causing malfunctions.

If cuts are consistently too shallow, leading to unstripped portions, adjust the cutting parameter size to increase the depth.

Check the clearance between the wire feeding drive wheels. If this gap is too large, adjust it to ensure proper wire grip. Thoroughly clean the wire feeding wheel and the blade retraction wheel of any contaminants that might impede their function.

Finally, ensure your air supply is normal. Insufficient air pressure can significantly affect the stripping process.

If, after trying all these steps, the problem persists, it's best to contact the automatic wire stripping machine manufacturer or a qualified technician for further inspection and maintenance.

评论

发表评论