Tangled wires can quickly derail any project, but the manual copper wire stripping machine offers a compact and precise solution to this common problem. This tabletop powerhouse puts you in control of your wire processing, making quick work of even complex tasks.

Getting Started: Setup and Power

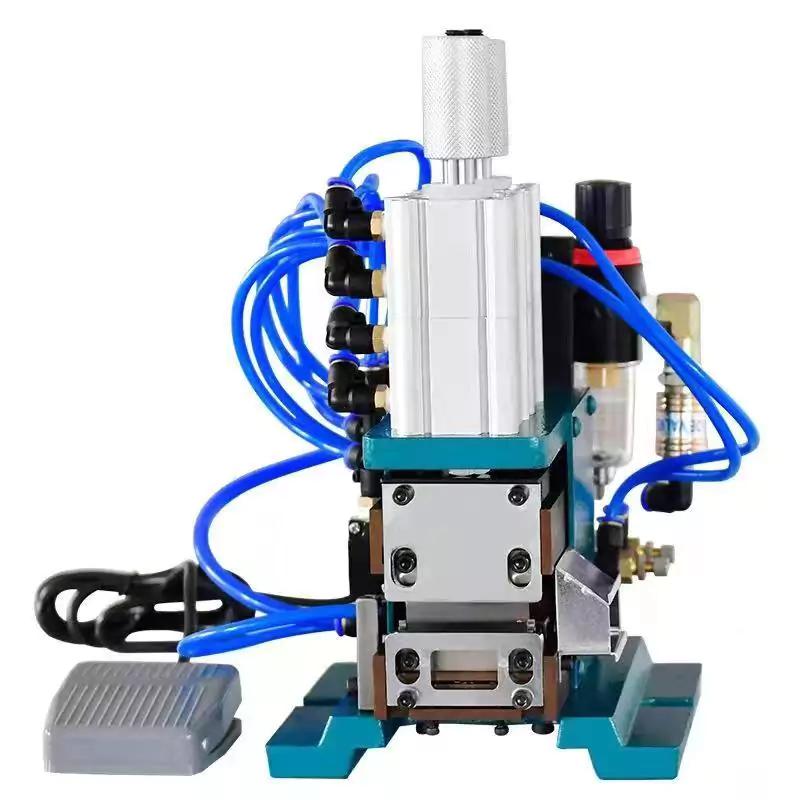

Before you begin, ensure your machine is properly set up. Connect the air supply hose to a reliable source, ideally providing 4.5-7 kg/cm² of pressure, such as a mini air compressor. Next, plug the unit into a standard 220V power outlet. With these simple steps, your stripping companion is ready for action.

Hands-On Control: Operating the Machine

Unlike fully automated systems, this manual machine thrives on your direct input. The foot switch is your primary control. A gentle press activates the internal cylinder, which is the core mechanism, giving you precise command over each stripping cycle.

Alibrating for Perfection: Adjusting for Wire Size

Optimizing the machine for different wire gauges is essential for clean, efficient stripping. Locate the headless screw, which governs the position of the upper clamp block and the movement of the stripping blade. By loosening the nut on this screw, you can adjust the gap between the components. Thicker wires will require a wider gap for proper stripping, while thinner wires need a tighter setting to ensure a clean cut without damage.

Achieving Precision: Stroke and Speed

Once you've set the ideal gap, secure the headless screw firmly in place. Use the main cylinder to feed the wire, fine-tuning the stroke length with the adjustment screw. If you need to modify the stripping speed, simply adjust the regulating valves – it's as straightforward as changing gears on a bicycle.

Enhanced Efficiency: Dual-Cutter Models

For increased productivity, consider a double-cutter model. These machines can simultaneously cut and strip wires, effectively doubling your efficiency. The calibration steps remain the same to ensure optimal performance.

Attention to Detail: Fine-Tuning Your Strips

True mastery lies in the details. Always maintain a 1.5mm gap between the cutter and the stripping blade to prevent wire damage. An overly wide gap can lead to uneven stripping. Pay attention to the gaskets as well; they dictate the stripping length. Adjust their thickness to achieve precise control over how much insulation is removed.

A Versatile and Cost-Effective Solution

The manual copper wire stripping machine is incredibly versatile. It handles multi-core cables with ease and effectively strips both sheath and shield wires. This cost-effective solution is not only precise but also energy-efficient. By incorporating this robust tabletop tool into your workflow, you'll gain unparalleled control and efficiency in all your wire processing endeavors.

评论

发表评论