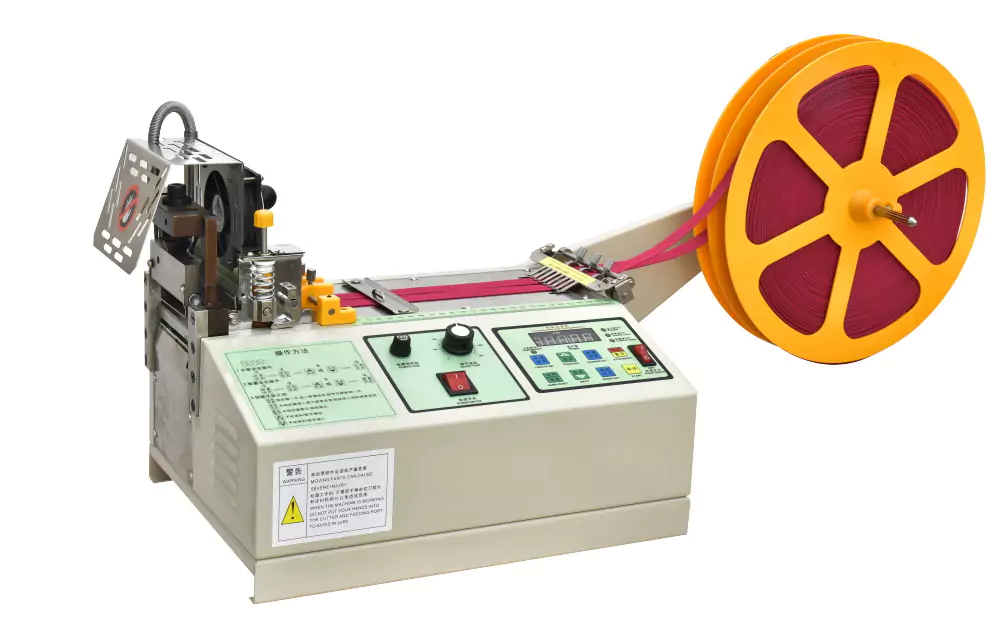

Encountering problems with your Roll-to-Sheet Cutting Machine can be frustrating, especially when deadlines for grosgrain ribbon printing and cutting projects loom. Don't worry! This guide covers common malfunctions and their straightforward solutions, helping you restore your machine's performance and ensure smooth, accurate cuts.

Pinpointing the Problem: Common Causes of Cutting Malfunctions

Several factors can lead to cutting inconsistencies. Let's break down typical issues and how to fix them:

1. Worn or Damaged Cutting Components:

Knife Bearing Failure: A compromised or broken knife bearing can prevent the cutting blade from moving smoothly.

Solution: Inspect the bearing; replace it if it shows signs of wear or breakage.

Dull Middle Knife: If the middle knife is blunt or damaged, your cuts will likely be uneven.

Solution: Either replace the knife entirely or, if available, rotate it to use an unblunted side.

2. Tension and Alignment Problems:

Broken Tube Pin: This small component is vital for maintaining proper material tension.

Solution: Use a small punch tool to secure or replace a broken pin.

Excessive Adjustment Tension: Over-tightening can lead to inaccurate cuts.

Solution: Locate the hexagon socket set screw and reduce the tension until it's appropriate for your material.

3. Material Feeding Difficulties:

Greasy Sheet or Drive Belt: Oil contamination on the material or drive belt can cause slippage.

Solution: Thoroughly clean all affected parts and reassemble them correctly.

Loose Transmission Belt: A slack belt means the material won't feed consistently during cutting.

Solution: Tighten the transmission belt by adjusting the frame seat or repositioning the motor.

Incorrect Roller Gap for Thin Materials: If the gap between the unwinding rollers is too narrow, thin materials like PP strap can experience cutting issues.

Solution: Adjust the roller gap to match the specific thickness of your material.

4. Sensor Malfunctions:

Faulty Magnetron (Belt Cutting Sensor): This sensor detects the material's presence, crucial for precise cuts.

Solution: If you suspect issues with magnetic sheets or sensor damage, refer to your user manual or contact a certified technician for diagnostic steps.

5. Crossbar Imbalance:

Improper Crossbar Balance: An unbalanced crossbar directly impacts cutting precision.

Solution: Adjust the crossbar to its optimal balanced position to ensure stable and smooth operation.

Ensuring Smooth Operation and Longevity

By understanding these common problems and their fixes, you can effectively address minor issues with your Roll-to-Sheet Cutting Machine, ensuring your grosgrain ribbon printing and cutting tasks proceed without unnecessary delays. Always consult your user manual for detailed instructions and consider professional assistance for more complex repairs.

Investing in Longevity:

Regular maintenance is key to extending the life of your machine. Adhering to the manufacturer's recommended cleaning and maintenance schedule can proactively prevent many of these issues, saving you time and effort in the long run.

With proactive upkeep and the ability to troubleshoot minor hitches, your Roll-to-Sheet Cutting Machine will continue to operate efficiently, providing consistent, high-quality results for all your ribbon cutting and printing needs.

评论

发表评论